About

We have 4 manufacturing Facilities under KOMPRAR Group. All facilities are ISO 9000 compliant. Every facility has got its unique advantage and skill set. From RFQ stage only, we decide which facility to use considering Industry we serve, Location of need & Technical Feasibility. This give us edge over others in techno-commercial competitiveness & solution under one roof.

Measurement Equipment

- Co-ordinate Measurement Machine

- Vision Measurement System

- Spectro Chemical Properties Machine

- Plating Thickness Tester

- Hardness Tester

- Surface Roughness Tester

Industries We Serve

- Electro-Mechanical Equipment

- Food & Dairy Equipment

- Automotive

- Infrastructure

- Flow Control Measurements

- Hydraulics

- Oil & Gas

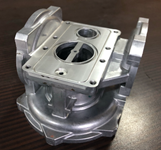

Manufacturing Facilities

- CNC Turning Centres : 20 nos.

- VMC: 10 nos.

- Traub and Automat machines: 20 nos.

- Broaching machines: 2 nos.

- Centreless grinding machine: 1 no.

- Internal/External threading machine: 1 no.

Manufacturing Locations

- Vasai (near Mumbai): JV 25,000 sqft

- Vasai, THANE (Mumbai): JV 9000 SFT

Core Processes

- Turning

- Milling

- Drilling

- Threading

- Profile Machining

- Grooving

Additional Processes

- Broaching

- Boring

- Rimming

- Grinding

- Polishing

List of Raw Material that we deal with..

- Stainless steel SS 316/316L/304/303/ 410Low carbon steel

- Cast Iron

- Phosphor Bronze

- Beryllium copper

- Alloy Steel 4140 - 80/110/125 KSI

- Die Steel P20

- Aluminium 6061 T6

- SG Iron

- Aluminium Nickel Bronze

- Brass

Outsourced processes – Surface treatment

- Powder coating

- Painting

- Anodizing

- Electroplating

- Chrome plating

- Electropolishing

- Zinc plating and Zinc Nickel plating

- Xylan Fluoropolymer coating

Heat treatment processes -

- Case Carburizing

- Solution Annealing

- Induction Hardening

- Other heat treatment

Special application process

- Vacuum brazing

- Sub zero treatment